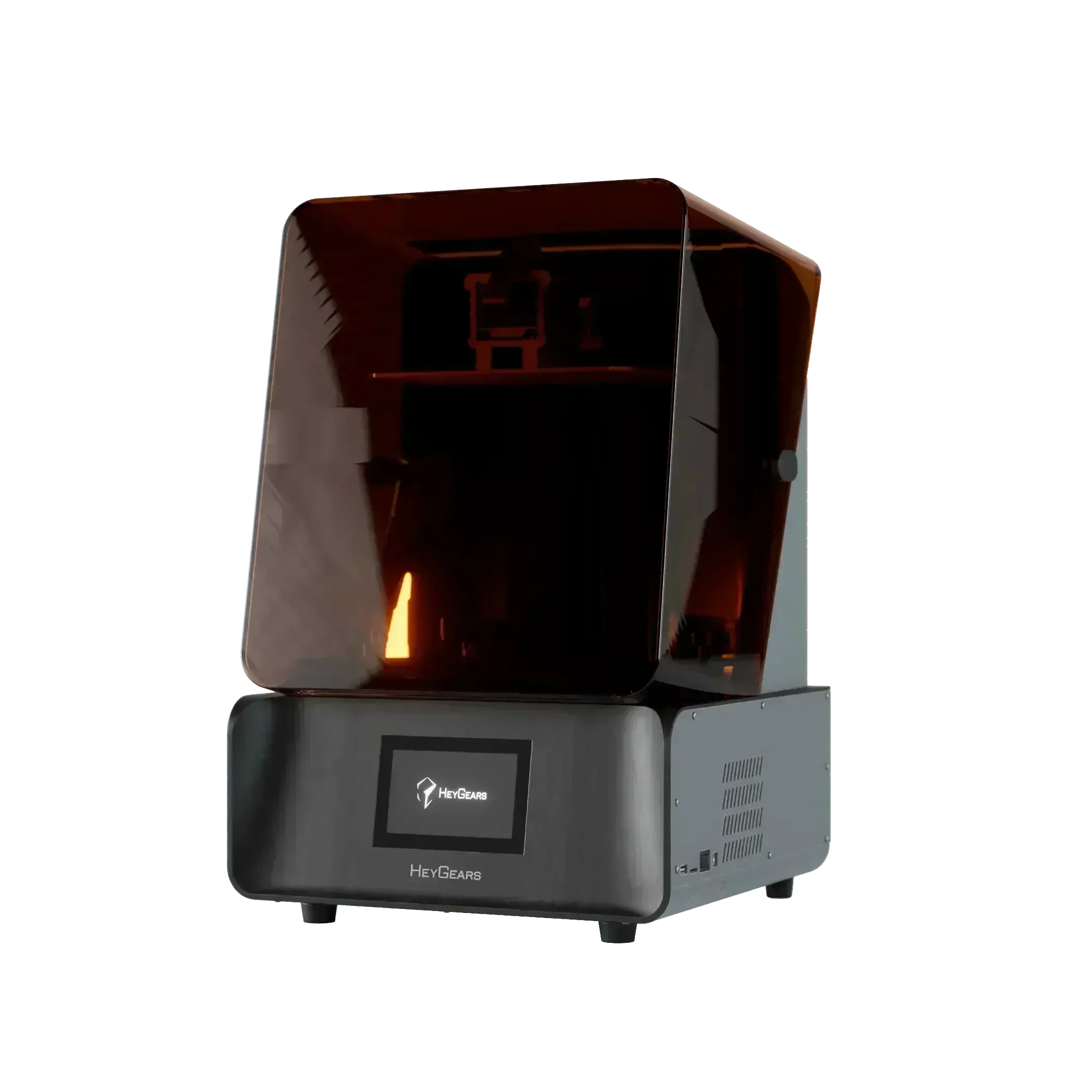

Heygears UltraCraft Reflex RS MSLA Resin 3D Printer

Need it faster? Contact us via phone or email for expedited delivery.

Popular items sell out fast. Pre-order now and we'll restock & ship from Germany within 5-10 working days.

Heygears UltraCraft Reflex RS MSLA Resin 3D Printer

The UltraCraft Reflex RS 3D Printer from HeyGears is a versatile and advanced machine designed for high-quality and efficient 3D printing.

Key Features and Innovations of UltraCraft Reflex RS

High Precision and Stability

-

Equipped with a C5-grade Z-axis module, ensuring consistent layer thickness and crisp, detailed prints.

-

Full-field screen calibration guarantees uniform accuracy across the entire printing area.

Enhanced Speed with Dynamic Motion Algorithm 3.0

-

Achieves up to a 33% increase in printing speed, leveraging HeyGears Lab-tested PAWW10 water-washable resin.*

-

Optimized for faster model production without compromising quality.

Advanced Auto-Assisted Printing System

-

Floating Screen Auto Leveling: Simplifies setup for accurate and reliable prints.

-

Automatic Resin Refill: Ensures uninterrupted printing by managing resin levels.

-

Automatic Resin Heating: Enhances material performance with the RS Heated & Pulsing Release Resin Tank (sold separately).

More Features of UltraCraft Reflex RS

High Precision and Performance:

-

Offers a resolution of 29.7 μm, ensuring detailed and accurate prints.

-

Powered by smart AI algorithms, including intelligent peeling force management for improved print reliability.

Convenient and Automated Features:

-

Equipped with auto resin level detection and auto resin refill, reducing manual intervention.

-

Includes an auto-heated tray for consistent material performance.

Integrated Workflow:

-

Part of a comprehensive ecosystem, enabling a seamless transition from printing to washing and curing.

-

Optimized dual curing enhances the durability and functionality of the printed materials.

User-Friendly Operation:

-

Designed for a hassle-free printing experience, minimizing the need for parameter adjustments.

-

Ideal for both professionals and advanced hobbyists who need a robust and versatile solution for complex designs.

RS Resin vs. Traditional 3D Printers Performance Comparison

According to data from HeyGears Lab, using PAWW10 water-washable resin, RS resin technology demonstrates significant advantages over traditional motion control 3D printers in both printing efficiency and quality. The comparison clearly shows that RS resin not only reduces printing time but also ensures high-quality output.

Key Features:

-

Faster Printing Speed:The model with 1121 layers printed with RS resin takes only 95 minutes, while the same model printed with traditional 3D printers takes 198 minutes, reducing the print time by 52% and significantly improving productivity.

-

More Efficient Low-Layer Printing:For the 561-layer model, using RS resin takes 71 minutes, compared to 107 minutes with traditional 3D printers, resulting in a 33% reduction in print time.

-

Balanced Speed and Quality: RS resin technology not only increases printing speed but also ensures high-quality results. The water-washable resin technology makes the printing process more efficient, and suitable for high-quality, fast printing needs, making it ideal for both professional and hobbyist users.

Test Model Results

*Data sourced from HeyGears Lab, 96% of movement errors are within 1 um, and 99.9% of the errors are no more than 2μm.

*Data sourced from HeyGears Lab, 96% of movement errors are within 1 um, and 99.9% of the errors are no more than 2μm.

Full-Field Precision Screen

To achieve printing high accuracy and reliability, we partition the screen into 60 zones and calibrate it with a full-screen tool, ensuring light intensity variation remains within ±3% for a printing tolerance of ≤0.05mm.

Printed Results Assembly Comparison

The RS automatically calibrates the screen using NFCdata, keeping light intensity differences within 5% and reducing variations in light intensity to ensure

printing precision after screen replacement.

Adaptive Z-axis Compensation

Combinations of Different Angles

The process package allows the RS printer to adjust the Z-axis compensation adaptively for each resin, to support up to 180 combinations of different angles, hole sizes, and edge types.

Z-axis Compensation Comparison

Z-axis Compensation Comparison

This approach minimizes deformation and resin buildup on support surfaces and reduces post-processing time compared to using just a single z-axis compensation parameter.

Dynamic Motion Algorithm 3.0 - 33% Increase in Print Speed

Single-Layer Dynamic Motion Control

Utilizing a seven-segment motion control logic per layer, the RS reads real-time force sensor data at 80 times per second, allowing it to adjust motion parameters efficiently, reducing redundant time, and preventing printing failures.

Comprehensive Dynamic Motion Control

This algorithm assesses printing difficulty for each layer using factors like cross-sections, part spacing, and quantity, selecting from 18 optimized motion control parameters to ensure quality while enhancing the speed.

This algorithm assesses printing difficulty for each layer using factors like cross-sections, part spacing, and quantity, selecting from 18 optimized motion control parameters to ensure quality while enhancing the speed.

Automatic Pre-processing

Complete Pre-processing in Just One Minute

One-click slicing without manual adjustment.

Automatic Repair Prevents Failures

Automatically detects and repairs model defects such as inverse normals, holes, and intersecting shells.

Intelligent Auto-Supports

Intelligently configured scaffold supports result in reduced detachments and a higher printing success rate.

Force Value Monitoring System

Residue Detection

Force sensors with a sensitivity of 0.1 N can detect resin residue as small as 0.2 mm and can auto-stop upon detection or print failure.

Printing Analysis

A report is produced after each print to accurately identify issues

Automated Printing Assistance

Floating Screen Auto Leveling

A floating screen system with a deviation of 0.15° eliminates gaps of up to 240 μm for automatic leveling.

1. General Shipping Information

- We provide premium shipping methods with a tracking number for each order.

- Shipping addresses must be entered in English without special symbols to help the courier company recognize your address in the system. We will ship strictly according to the shipping address you provided. Please notify us of any address change before your order is marked "Shipped" to avoid parcel loss.

- Please contact our customer service staff immediately if you need to cancel or change an order. Once your order has reached "Shipped" status, it can no longer be canceled or changed in any way. To avoid complications, please recheck your shopping cart before checkout.

- We can ship all in-stock orders within 1 business day after your order has been confirmed.

- All items are inspected before dispatch and are carefully hand-packed.

- With standard courier practice, you need to check the contents of the parcel before signing for your goods. Otherwise, we will not be held responsible for any damage that may have occurred in transit.

🚀 Need Faster Shipping?

If you require expedited shipping (Express), please contact our customer support team at info@openelab.io for a customized quote tailored to your location.

2. Shipping Rates & Options

Our shipping rates are calculated based on the order value and destination. Please refer to the tables below for details.

2.1 Germany (Domestic)

| Shipping Method | Order Value | Cost | Est. Delivery |

|---|---|---|---|

| Deutsche Post | €0 - €50.00 | €4.95 | 2-4 Business Days |

| Deutsche Post | Over €50.00 | Free | 2-4 Business Days |

|

DHL Paket (Faster Delivery) |

€0 - €50.00 | €6.95 | 1-3 Business Days |

|

DHL Paket (Faster Delivery) |

€50.00 - €100.00 | €2.00 | 1-3 Business Days |

|

DHL Paket (Faster Delivery) |

Over €100.00 | Free | 1-3 Business Days |

2.2 European Union (EU)*

*Including:

| Shipping Method | Order Value | Cost | Est. Delivery |

|---|---|---|---|

| Deutsche Post | €0 - €100.00 | €7.95 | 5-9 Business Days |

| Deutsche Post | Over €100.00 | Free | 5-9 Business Days |

|

DHL Paket (Faster Delivery) |

€0 - €100.00 | €15.95 | 3-7 Business Days |

|

DHL Paket (Faster Delivery) |

€100.00 - €250.00 | €7.95 | 3-7 Business Days |

|

DHL Paket (Faster Delivery) |

Over €250.00 | Free | 3-7 Business Days |

2.3 United States

| Region | Shipping Method | Order Value | Cost | Est. Delivery |

|---|---|---|---|---|

|

Continental U.S. (50 States) |

USPS Ground Advantage | €0 - €45.00 | €5.95 | 3-7 Business Days |

| USPS Ground Advantage | Over €45.00 | Free | 3-7 Business Days | |

| USPS Priority Mail | €0 - €45.00 | €16.95 | 1-4 Business Days | |

| USPS Priority Mail | Over €45.00 | €14.95 | 1-4 Business Days | |

|

Non-Continental U.S. (AK, HI, PR, etc.) |

USPS Ground Advantage | €0 - €60.00 | €6.95 | 5-9 Business Days |

| USPS Ground Advantage | Over €60.00 | Free | 5-9 Business Days |

* The regions in the Non-Continental U.S. include: Alaska, American Samoa, Guam, Hawaii, the Marshall Islands, the Northern Mariana Islands, Palau, Puerto Rico, the U.S. Virgin Islands, and all U.S. Armed Forces addresses. The shipping and delivery to these areas are subject to the Non-Continental U.S. shipping rules.

2.4 International (Outside EU)

For specific international destinations, including Switzerland, United Kingdom, and Norway.

| Order Amount | Shipping Cost |

|---|---|

| €0 - €300.00 | €19.95 |

| Over €300.00 | Free |

Important Notice:

- Inventory Status: Please check the inventory status on the product page. Our system displays real-time stock for our Munich and Long Beach warehouses. If an item is out of stock in these locations, it will be marked as "Pre-order". You can still place an order for these items.

- Pre-order Fulfillment: For "Pre-order" items, we arrange the most efficient logistics solution to ensure you receive your goods as quickly as possible. Your package may be shipped directly from our Shenzhen warehouse. Alternatively, as part of our standard restocking process, we may transport the goods to our Munich or Long Beach warehouse first (typically taking 5-10 business days) before dispatching them to you.

- Split Shipments: If your order contains both in-stock and Pre-order items, we will prioritize shipping the in-stock items from the local warehouse immediately. The remaining Pre-order items will be sent to you in a separate shipment once they are ready.

3. International Warehouse

Our products are stored in our Munich, Long Beach, and Shenzhen warehouses to provide more flexible logistics solutions tailored to different regions and customer needs. On each product's description page, we indicate the specific warehouse location to help you better plan your purchase and delivery schedule.

3.1 German Warehouse

For products stored in our warehouse in Munich, we use either Deutsche Post or DHL for shipping, depending on the size of the package. Logistics within Germany are very efficient, with an estimated delivery time of 2-4 business days, ensuring you receive your order quickly and conveniently. For Western EU countries, the estimated delivery time is 4-6 business days. For Eastern EU countries, the estimated delivery time is 6-8 business days.

3.2 US Warehouse

For products stored in our warehouse in Long Beach, we use either USPS or UPS for shipping, depending on the size of the package. Logistics within U.S. are very efficient, with an estimated delivery time of 3-7 business days, ensuring you receive your order quickly and conveniently.

3.3 Chinese Warehouse

For Pre-order items or orders fulfilled directly from our Shenzhen warehouse, we utilize YunExpress for reliable international shipping. Given the complexities of international shipping, the estimated delivery time for these packages is around 10 business days, though this may vary slightly due to customs processes or other uncontrollable factors. Otherwise, products will be restocked to our Munich or US warehouses before final delivery, as detailed in the "Important Notice" above.

4. Customs and Taxes

4.1 How are customs handled by OpenELAB for import or export?

For EU Member States: Whether shipped from Germany or China, we cover all import duties and taxes (DDP), ensuring that you receive your package without any additional costs or hassle with customs.

For countries outside of the European Union, such as Switzerland and Norway, you may be subject to import duties, taxes, and/or customs fees charged upon delivery. These fees vary from country to country and are the sole responsibility of the recipient.

⚠️ Refusal of Delivery: If you refuse to pay these fees upon delivery and the package is returned to us, the refund amount will be calculated after deducting the original shipping costs, return shipping costs, and any applicable customs or storage fees.

4.2 How is VAT charged when the Customer places an order from OpenELAB?

In accordance with the newest VAT e-commerce rules in the EU, OpenELAB shall have the right to charge the amount of VAT at checkout. The standard rate of actual VAT applied is subject to the destination country's regulations. No additional VAT will be charged upon delivery for these orders.

openelab.de

openelab.de

openelab.com

openelab.com