Introduction to Heygears UltraCraft Reflex RS

The 3D printing industry has seen significant advancements in recent years, with companies continuously striving to push the boundaries of what's possible with additive manufacturing. Among these innovators is Heygears, a company that has introduced a new level of precision and performance with its UltraCraft Reflex RS 3D Printer. This printer is designed for both hobbyists and professionals who demand high-quality prints with minimal post-processing, making it a standout choice in the crowded market of desktop 3D printers.

The Genesis of UltraCraft Reflex RS

Heygears UltraCraft Reflex RS was developed with the vision to redefine the standards of desktop 3D printing. Here's what makes this printer unique:

-

High-Resolution Printing: With a native resolution of 2560 x 1620, it achieves a level of detail that was previously the domain of much more expensive industrial printers.

-

DLP Technology: Utilizing Digital Light Processing (DLP) technology, the Reflex RS offers a stable light source for consistent curing, ensuring high-quality prints with excellent surface finish.

Key Features of Heygears UltraCraft Reflex RS

Precision Engineering

The Reflex RS is built on the foundation of precision engineering:- Laser Engraving: The print bed is laser engraved for precise leveling, ensuring uniform layer thickness and reducing the need for manual adjustments.

- Dual-Resolution Mode: Users can choose between high-resolution and ultra-high-resolution printing, allowing for flexibility in project requirements.

- The printer boasts a build volume of 126 x 80 x 200 mm, which is substantial for a desktop printer, offering ample space for various project sizes.

- It supports a range of high-quality resins, including standard, high-toughness, and transparent types, catering to different applications from prototypes to functional parts.

User Experience

Heygears has focused on creating an intuitive user experience:

-

Automated Calibration: The Reflex RS features an automatic calibration system that ensures the print head and bed are perfectly aligned.

-

Intuitive Software: Heygears' proprietary software, UltraCraft, provides a user-friendly interface for model preparation, slicing, and printer control.

Print Preparation

-

Model Import: Import your 3D models in various formats like STL, OBJ, or AMF.

-

Support Structures: The software automatically generates supports where necessary, minimizing the user's need for manual intervention.

-

Slicing: Advanced slicing algorithms ensure optimal layer adhesion and support removal.

Control and Monitoring

-

Touchscreen Interface: The printer comes with a 7-inch touchscreen for easy navigation and control.

-

Live Monitoring: Users can monitor the print progress through the touchscreen or remotely via the UltraCraft software.

Performance and Speed

The Reflex RS stands out for its printing speed and performance:

-

Fast Print Speeds: With print speeds reaching up to 55mm/h in high-resolution mode, it significantly reduces printing time without sacrificing quality.

-

Consistent Quality: The DLP light source ensures uniform curing across the entire build platform, providing consistent results.

Speed Optimization

-

Layer Thickness: The printer supports layer thicknesses down to 0.03mm in ultra-high-resolution mode, allowing for fine details and smooth surfaces.

-

Resin Flow: A high-precision resin vat ensures an even resin flow, which is critical for maintaining print speed and quality.

Post-Processing

Post-processing with the Reflex RS is made straightforward:

-

Minimal Support Removal: The printer's ability to produce parts with minimal support structures means less time spent on post-processing.

-

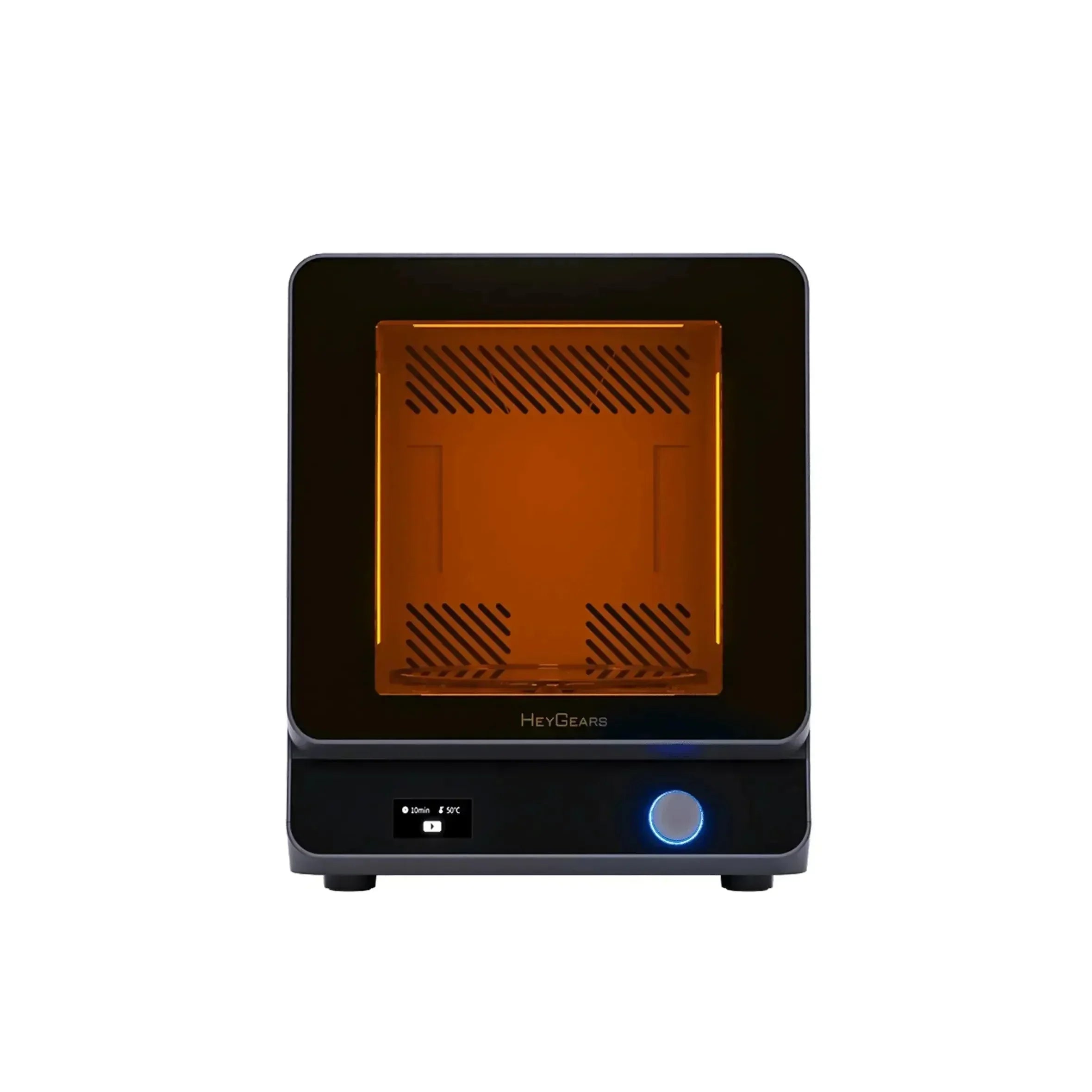

Cleaning and Curing: Heygears offers a companion wash and cure station that simplifies the process of cleaning and post-curing prints.

Cleaning Station

-

Ultrasonic Cleaning: The cleaning station uses ultrasonic waves to remove uncured resin, ensuring thorough cleaning without manual scrubbing.

Curing Station

-

360-degree Curing: A rotating platform ensures even UV exposure for curing, resulting in stronger parts with excellent surface finish.

How to Use Heygears UltraCraft Reflex RS

Setting Up Your Printer

-

Unboxing: Carefully unpack the Reflex RS, ensuring all components are present.

-

Assembly: Assemble the printer following the detailed manual provided.

-

Software Installation: Download and install the UltraCraft software from Heygears' website.

-

Calibration: Run the automatic calibration process to ensure the printer is ready for optimal printing.

Preparing Your Model

-

Import Your Model: Use the UltraCraft software to import your 3D model.

-

Orientation: Adjust the orientation of your model for optimal printing and support generation.

-

Supports: Let the software generate supports or manually add them where necessary.

-

Slicing: Slice your model, choosing the desired resolution and layer thickness.

Printing Process

-

Resin Preparation: Fill the resin vat with the appropriate resin for your project.

-

Start Printing: Use the touchscreen or software to start the print job.

-

Monitor: Keep an eye on the print through the touchscreen or software for any issues.

Post-Processing

Introduction to Heygears UltraCraft Wash and Cure

Heygears has not only provided an exceptional 3D printer with the UltraCraft Reflex RS but also complements it with an integrated post-processing solution, the UltraCraft Wash and UltraCraft Cure. These devices streamline the process of cleaning and curing your 3D prints, ensuring that your final products are of the highest quality with minimal effort.

Understanding the Post-Processing Workflow

The post-processing of 3D printed resin models involves two main steps:

-

Washing: Removing excess uncured resin from the printed parts.

-

Curing: Fully hardening the resin under UV light to achieve the desired mechanical properties.

Using Heygears UltraCraft Wash

Preparation for Washing

Before you begin, ensure that:

-

Your 3D printed parts are still on the build platform.

-

You have isopropyl alcohol (IPA) or a resin cleaner recommended by Heygears.

Operating the UltraCraft Wash

Loading the Parts

-

Remove the Build Platform: Gently remove the build platform from the printer, ensuring not to disturb the printed parts.

-

Prepare the Basket: Place the printed parts into the wash basket. Make sure they are not overcrowded, allowing the cleaning solution to reach all surfaces.

Adding Cleaning Solution

-

Fill the Wash Tank: Fill the tank with the cleaning solution, following the manufacturer's recommendations for the correct amount and type of solution.

-

Ensure Adequate Liquid Level: The parts should be fully submerged in the cleaning solution for effective cleaning.

Starting the Wash Cycle

-

Place Basket in Tank: Lower the basket into the wash tank, ensuring the parts are completely covered by the cleaning solution.

-

Select Wash Time: Use the touchscreen or control panel to select the appropriate wash time. Heygears typically recommends around 5-10 minutes, but this can vary based on the complexity of the prints.

-

Initiate Wash: Start the cleaning cycle. The wash station will agitate the cleaning solution to help remove uncured resin from the prints.

After Washing

-

Remove Basket: Once the wash cycle is complete, lift the basket out of the cleaning solution.

-

Drain and Dry: Allow the parts to drip any excess cleaning solution back into the tank. Use a lint-free cloth or compressed air to gently dry the parts.

Using Heygears UltraCraft Cure

Preparing for Curing

-

Ensure the parts are clean and free from any excess resin or cleaning solution.

-

Have a set of gloves and eye protection ready, as UV light can be harmful.

Operating the UltraCraft Cure

Loading the Parts

-

Position the Parts: Place your cleaned parts on the curing platform. Ensure they are not touching each other to allow for even UV exposure.

Setting Up the Cure

-

Select Curing Time: Use the touchscreen to set the curing time. The recommended time can vary but typically ranges from 10 to 30 minutes.

-

Adjust Platform: If your UltraCraft Cure has an adjustable platform, set the height for optimal UV exposure.

Initiating the Cure

-

Start Curing: Start the curing process. The platform will rotate, and the UV lights will cure the parts from all angles.

After Curing

-

Cool Down: Allow the parts to cool down after the curing process, as they might be hot to the touch.

-

Inspect and Finish: Inspect your parts. If necessary, sand or polish any areas that might need additional refinement.

Tips for Optimal Results

-

Cleaning Solution: Regularly replace or refresh the cleaning solution to ensure effective cleaning.

-

Resin Compatibility: Use the recommended cleaning solution for your specific resin type.

-

Safety: Always wear protective gear when handling cleaning solutions and UV light.

-

Curing Time: Experiment with curing times to find the optimal duration for your prints. Over-curing can lead to brittleness.

-

Batch Processing: You can process multiple parts at once, but ensure they are not too close together to allow for proper cleaning and curing.

Conclusion

The Heygears UltraCraft Reflex RS 3D Printer is a game-changer for desktop 3D printing, offering precision, speed, and user-friendliness in one package. Whether you're a hobbyist looking to create intricate models or a professional needing reliable prototyping, the Reflex RS provides tools to bring your designs to life with unparalleled quality. Its focus on automation and simplicity in the printing process makes it an excellent choice for anyone looking to dive into the world of 3D printing or elevate their existing workflow.

And the Heygears UltraCraft Wash and Cure stations provide an efficient and user-friendly solution for post-processing your 3D prints. By following these steps, you can ensure that your printed parts are not only clean but also fully cured, ready for use or further finishing. With Heygears' commitment to quality and precision, you're equipped to achieve professional results from your desktop 3D printing setup.

openelab.de

openelab.de

openelab.com

openelab.com