Uiterlijksoverzicht en productspecificaties van de Xiaomi CyberGear Motor Driver

Geïntegreerde 24V Voeding en CAN Communicatieterminals

-

24V DC Voeding: De driver ondersteunt een standaard 24V DC voeding, wat zorgt voor een stabiele werking in verschillende werkomgevingen.

-

CAN Communicatie-interface: De geïntegreerde CAN (Controller Area Network) interface maakt efficiënte communicatie met andere elektronische systemen mogelijk, wat zorgt voor een hogere systeemintegratie en snellere responstijden.

Hardwareversie en lasergegraveerd QR-code

-

Laser-gegraveerde QR-code: De QR-code op de behuizing van de driver zorgt voor productuniciteit, waardoor snelle traceerbaarheid en beheer mogelijk zijn, wat de after-sales service en kwaliteitscontrole vereenvoudigt.

-

Identificatie van de Hardwareversie: Duidelijk gemarkeerde hardwareversies stellen technici in staat om snel modellen te identificeren voor systeemupgrades, compatibiliteitscontroles en onderhoud.

MCU Downloadpoort

De bestuurder is uitgerust met een speciale MCU (Microcontroller Unit) downloadpoort voor firmware-updates en systeemdebugging. Technici kunnen deze poort gebruiken om snel nieuwe firmware te uploaden, de systeemprestaties te optimaliseren of realtime probleemoplossing uit te voeren.

CAN Communicatie Testpunten

Voor assemblage- en onderhoudsgemak beschikt de bestuurder over speciale testpunten voor CAN-communicatie. Technici kunnen de integriteit en functionaliteit van communicatielijnen verifiëren, wat de efficiëntie van het debuggen en het oplossen van fouten aanzienlijk verbetert.

Indicatielampje Ontwerp

Meerdere indicatorlampjes zijn voorzien om de operationele status van de bestuurder en het systeem weer te geven:

-

Voeding Indicator: Geeft aan of het apparaat normaal stroom ontvangt.

-

Signaal Indicator: Weerspiegelt de communicatiestatus en signaaloverdracht, en helpt bij het monitoren en identificeren van potentiële problemen.

Gestandaardiseerde Montagegaten

De behuizing van de bestuurder is ontworpen met gestandaardiseerde montagegaten om een veilige installatie op compatibele voertuigen of apparatuur te waarborgen. Dit ontwerp verbetert de installatie-efficiëntie en verhoogt de operationele betrouwbaarheid.

Driefasige Wikkeling Terminals (C, A, B)

-

Efficiënte Verbinding: Gestandaardiseerde laspunten zorgen voor een veilige en efficiënte verbinding tussen de motorwikkelingen en de driver.

-

Stabiele Vermogensoverdracht: Geoptimaliseerde samenwerking tussen de motor en de driver verbetert de operationele betrouwbaarheid en de algehele efficiëntie.

| Artikelspecificatie | |

| Beoordeelde Bedrijfsspanning | 24VDC |

| Maximale Toegestane Spanning | 28VDC |

| Beoordeelde Bedrijfstroom | 6.5A |

| Maximale Toegestane Stroom | 23A |

| Stand-by-stroomverbruik | ≤18mA |

| CAN-bus bitsnelheid | 1 Mbps |

| Afmetingen | Φ58mm |

| Bedrijfsomgeving Temperatuur | -20°C tot 50°C |

| Maximale Toegestane Temperatuur voor Besturingspaneel | 80°C |

| Encoderresolutie | 14bit (Enkele Omwenteling Absoluut) |

Stuurinterface-definities

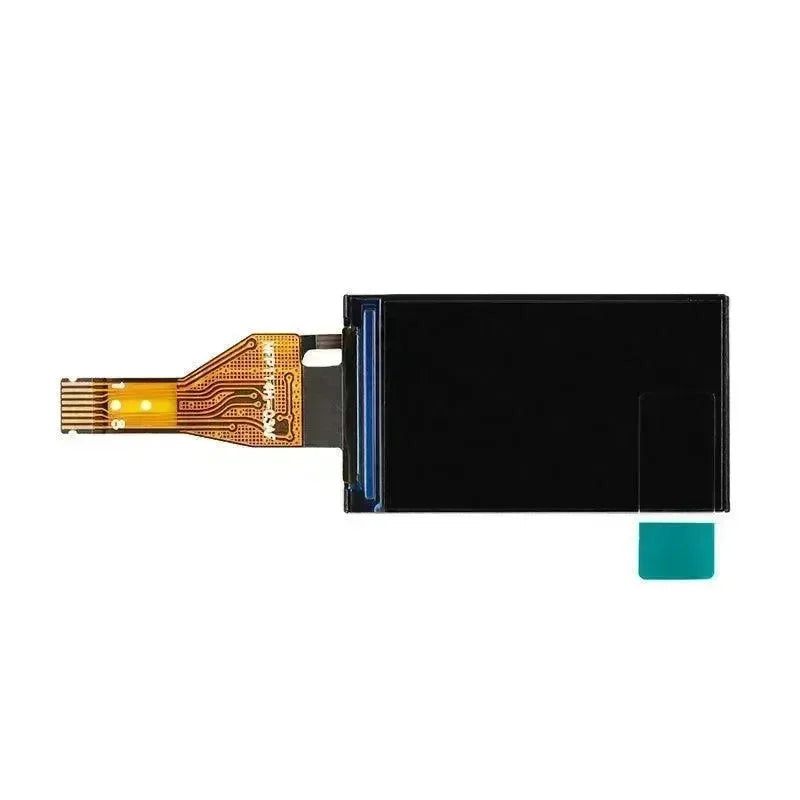

Aansluitingsdiagram

Aanbevolen modellen voor schijfinterface

| Serienummer. | Model aan de zijkant van het bord | Draadzijde model |

| 1 | XT30PB(2+2)-M.G.B | XT30(2+2)-F.G.B |

| 2 | 2,0 mm-2P soldeerpad | 2,0 mm-2P-sonde |

| 3 | 2.54mm-4P soldeerpad | 2,54 mm-4P-sonde |

Definities van de aansluitpinnen van de stuurinterface

Voedingsaansluiting en CAN-communicatiepoort:

| Serienummer. | Interfacefunctie | Pin nr. | Beschrijving |

| 1 | Voeding en CAN-interface | 1 | Positief vermogen (+) |

| 2 | Macht negatief (-) | ||

| 3 | CAN Laag (CAN_L) | ||

| 4 | CAN Hoog (CAN_H) | ||

| 2 | CAN Communicatie Testpunten | 1 | CAN Laag (CAN_L) |

| 2 | CAN Hoog (CAN_H) | ||

| 3 | Downloadpoort | 1 | SWDIO (gegevens) |

| 2 | SWCLK (Klok) | ||

| 3 | 3V3 (positief 3,3V) | ||

| 4 | GND (aarde) |

Definitie van de rijindicator

| Indicatorlamp Definitie | Beschrijving |

| Voedingsindicatorlampje (Rood) | Het voedingsindicatorlampje wordt gebruikt om de 3.3V van de MCU aan te geven. voedingsstatus. Wanneer de totale ingangs spanning 24V is, de licht zal rood zijn, wat aangeeft dat het netwerk goed functioneert. Als de ingangsvermogen onder de 24V ligt, moet de indicator worden uitgeschakeld. |

| Signaalindicatorlamp (Blauw) | Het signaalindicatorlampje knippert wanneer de MCU is werkt normaal en de chip functioneert correct. |

Hoofdcomponenten en specificaties

| Serienummer. | Item | Onderdeel nummer | Hoeveelheid |

| 1 | MCU-chip | GD32F303RET6 | 1 stuk |

| 2 | Stuurprogramma-chip | 6EDL7141 | 1 stuk |

| 3 | Magnetische Encoder Chip | AS5047P | 1 stuk |

| 4 | Gevoelige weerstand | NXFT15XH103FEAB021/NCP18XH103F03RB | 2 kamers |

| 5 | Vermogen MOSFET | JMGG031V06A | 6 stuks |

-

MCU Chip: De microcontroller eenheid (MCU) fungeert als de 'hersenen' van het apparaat, verantwoordelijk voor het aansturen en coördineren van andere componenten.

-

Driver Chip: Dit component stuurt motoren of andere actuatoren aan door besturingssignalen om te zetten in aandrijfsignalen.

-

Magnetische Encoder Chip: Gebruikt om de snelheid en positie van de motor te detecteren, en biedt essentiële feedback voor nauwkeurige controle.

-

Thermistor: Houdt de temperatuur van het apparaat in de gaten, zorgt voor veilige werking en voorkomt oververhitting.

-

Kracht MOSFET: Een krachtsemiconductorapparaat dat vaak wordt gebruikt in motorstuurcircuits om efficiënt hoge vermogenssignalen in te schakelen en te regelen.

Besturingscommunicatieprotocol en gebruiksinstructies

De motorcommunicatie is een CAN 2.0 communicatie-interface met een baudrate van 1 Mbps en een uitgebreid frameformaat zoals hieronder weergegeven:

|

Gegevensdomein |

29-bits-ID |

8-byte gegevensveld |

||

|

Dimensie |

Bit28~bit24 |

stukje23~8 |

bit7~0 |

Byte0~Byte7 |

|

Beschrijving |

Type communicatie |

Datumgebied 2 |

doeladressen |

Gegevensgebied 1 |

De motor ondersteunt de volgende bedieningsmodi:

-

Uitgebreide Controlemodus: Stel vijf operationele controleparameters in voor de motor om geïntegreerde controle te bereiken.

-

Huidige modus: Geef de doel-Iq-stroom op om een nauwkeurige stroomregeling te bereiken.

-

Snelheidsmodus: Geef een doel-lopersnelheid op die de motor moet handhaven.

-

Positiemodus: Geef een doelpositie op, en de motor zal naar die positie bewegen en deze vasthouden.

Hoofdcomponenten en specificaties

| Serienummer. | Item | Onderdeel nummer | Hoeveelheid |

| 1 | MCU-chip | GD32F303RET6 | 1 stuk |

| 2 | Stuurprogramma-chip | 6EDL7141 | 1 stuk |

| 3 | Magnetische Encoder Chip | AS5047P | 1 stuk |

| 4 | Gevoelige weerstand | NXFT15XH103FEAB021/NCP18XH103F03RB | 2 kamers |

| 5 | Vermogen MOSFET | JMGG031V06A | 6 stuks |

-

MCU Chip: De microcontroller eenheid (MCU) fungeert als de "hersenen" van het apparaat, verantwoordelijk voor het besturen en coördineren van andere componenten.

-

Driver Chip: Dit component stuurt motoren of andere actuatoren aan door besturingssignalen om te zetten in aandrijfsignalen.

-

Magnetische Encoder Chip: Gebruikt om de snelheid en positie van de motor te detecteren, en biedt essentiële feedback voor nauwkeurige controle.

-

Thermistor: Houdt de temperatuur van het apparaat in de gaten, zorgt voor veilige werking en voorkomt oververhitting.

-

Kracht MOSFET: Een krachtsemiconductorapparaat dat vaak wordt gebruikt in motorstuurcircuits om efficiënt hoge vermogenssignalen in te schakelen en te regelen.

Besturingscommunicatieprotocol en gebruiksinstructies

De motorcommunicatie is een CAN 2.0 communicatie-interface met een baudrate van 1 Mbps en een uitgebreid frameformaat zoals hieronder weergegeven:

| Gegevensdomein | 29-bits-ID | 8-byte gegevensveld | ||

| Dimensie | Bit28~bit24 | stukje23~8 | bit7~0 | Byte0~Byte7 |

| Beschrijving | Type communicatie | Datumgebied 2 | doeladressen | Gegevensgebied 1 |

De motor ondersteunt de volgende bedieningsmodi:

-

Uitgebreide Controlemodus: Stel vijf operationele controleparameters in voor de motor om geïntegreerde controle te bereiken.

-

Huidige modus: Geef de doel-Iq-stroom op om een nauwkeurige stroomregeling te bereiken.

-

Snelheidsmodus: Geef een doel-lopersnelheid op die de motor moet handhaven.

-

Positiemodus: Geef een doelpositie op, en de motor zal naar die positie bewegen en deze vasthouden.

Beschrijving van het type communicatieprotocol

-

krijg apparaat-ID (communicatietype 0); krijg apparaat-ID en 664-bits MCU unieke identificatie

| Gegevensdomein | 29-bits-ID | 8-byte gegevensveld | ||

| Dimensie | Bit28~bit24 | stukje23~8 | bit7~0 | Byte0~Byte7 |

| Beschrijving | 0 | bit15~8: gebruikt om te identificeren de host CAN_ID |

Doelmotor CAN_ID | 0 |

| Gegevensdomein | 29-bits-ID | 8-byte gegevensveld | ||

| Dimensie | Bit28~bit24 | stukje23~8 | bit7~0 | Byte0~Byte7 |

| Beschrijving | 0 | Doelmotor CAN_ID | 0XFE | 64-bits MCU unieke identificatie |

-

De bedieningsmodus motorbesturingscommando's (communicatietype 1) worden gebruikt om besturingscommando's naar de motor te sturen.

| Gegevensdomein | 29-bits-ID | 8-byte gegevensveld | ||

| Dimensie | Bit28~bit24 | stukje23~8 | bit7~0 | Byte0~Byte7 |

| Beschrijving | 1 | Byte2: Koppel (0~65535) corresponderend met (-12Nm12Nm) |

Doel motor CAN _ID | Byte0~1:Doelhoek[0~65535] komt overeen met (-4π~4π) Byte2~3:Doel hoeksnelheid[0~65535] komt overeen met (-30rad/s~30rad/s) Byte4~5:Kp[0~65535] komt overeen naar (0,0~500,0) Byte6~7:Kd [0~65535] komt overeen met (0,0~5,0) |

-

Motorfeedbackgegevens (communicatietype 2) worden gebruikt om feedback te geven aan de hostcomputer over de motorstatus.

| Gegevensdomein | 29-bits-ID | 8-byte gegevensveld | ||

| Dimensie | Bit28~bit24 | stukje23~8 | bit7~0 | Byte0~Byte7 |

| Beschrijving | 2 | Bit8~Bit15: Huidig motor CAN-ID bit21~16: Foutmelding (0 nee 1 ja) bit21: Niet gekalibreerd bit20: HALL-code fout bit19: Magnetische codering schuld bit18: Over temperatuur bit17: Overstroom bit16: Onder spanning fout bit22~23: Modusstatus 0 : Reset-modus [Reset] 1: Cali-modus [Calibration] 2: Motormodus [Run] |

Host-CAN_ID | Byte0~1:Doelhoek[0~65535] komt overeen met (-4π~4π) Byte2~3:Doelhoek snelheid[0~65535] komt overeen tot(-30rad/s~30rad/s) Byte4~5:Kp[0~65535] komt overeen naar (0,0~500,0) Byte6~7:Kd [0~65535] komt overeen naar (0.0~5.0)Byte0~1:Huidige hoek[0~65535] komt overeen naar (-4π~4π) Byte2~3:Huidige hoek snelheid[0~65535] komt overeen tot(-30rad/s~30rad/s) Byte4~5:Huidig koppel[0~65535] komt overeen met (-12Nm~12Nm) Byte6~7: Huidig temperatuur:Temp(Celsius)*10 |

-

Motor inschakelen (communicatietype 3)

| Gegevensdomein | 29-bits-ID | 8-byte gegevensveld | ||

| Dimensie | Bit28~bit24 | stukje23~8 | bit7~0 | Byte0~Byte7 |

| Beschrijving | 4 | bit15~8: gebruikt om te identificeren de belangrijkste CAN_ID |

Doelmotor CAN_ID | Tijdens normale werking, de gegevensgebied moet worden gewist 0; Byte[0]=1: fout wissen; |

Antwoordframe: Antwoordmotorfeedbackframe (zie communicatietype 2)

-

Motor stop (communicatietype 4)

| Gegevensdomein | 29-bits-ID | 8-byte gegevensveld | ||

| Dimensie | Bit28~bit24 | stukje23~8 | bit7~0 | Byte0~Byte7 |

| Beschrijving | 4 | bit15~8: gebruikt om te identificeren de belangrijkste CAN_ID |

Doelmotor CAN_ID | Tijdens normale werking, de gegevensgebied moet worden gewist 0; Byte[0]=1: fout wissen; |

Antwoordframe: Antwoordmotorfeedbackframe (zie communicatietype 2)

-

Het instellen van de mechanische nulpositie van de motor (communicatietype 6) stelt de huidige motorpositie in op de mechanische nulpositie (verloren bij uitschakelen).

| Gegevensdomein | 29-bits-ID | 8-byte gegevensveld | ||

| Dimensie | Bit28~bit24 | stukje23~8 | bit7~0 | Byte0~Byte7 |

| Beschrijving | 6 | bit15~8: gebruikt om de hoofd CAN_ID te identificeren | Doelmotor CAN_ID | Byte[0]=1 |

Antwoordframe: Antwoordmotorfeedbackframe (zie communicatietype 2)

-

De motor CAN_ID instellen (communicatietype 7) Het wijzigen van de huidige motor CAN_ID heeft onmiddellijk effect.

| Gegevensdomein | 29-bits-ID | 8-byte gegevensveld | ||

| Dimensie | Bit28~bit24 | stukje23~8 | bit7~0 | Byte0~Byte7 |

| Beschrijving | 7 | Bit15~8: Gebruikt om de hoofd CAN_ID te identificeren. Bit16~23: Vooraf ingestelde CAN_ID |

Doelmotor CAN_ID | |

Antwoordframe: Antwoordmotorfeedbackframe (zie communicatietype 0)

-

Individuele parameterlezen (communicatietype 17)

| Gegevensdomein | 29-bits-ID | 8-byte gegevensveld | ||

| Dimensie | Bit28~bit24 | stukje23~8 | bit7~0 | Byte0~Byte7 |

| Beschrijving | 17 | bit15~8: gebruikt om de hoofd CAN_ID te identificeren | Doelmotor CAN_ID | Byte0~1: index, parameter kolommen Zie communicatietype 22 voor details. Byte2~3: 00 Byte4~7: 00 |

| Gegevensdomein | 29-bits-ID | 8-byte gegevensveld | ||

| Dimensie | Bit28~bit24 | stukje23~8 | bit7~0 | Byte0~Byte7 |

| Beschrijving | 17 | bit15~8: gebruikt om de hoofd CAN_ID te identificeren | Doelmotor CAN_ID | Byte0~1: index, zie communicatietype 22 voor parameterlijst. Byte2~3: 00 Byte4~7: parametergegevens, 1 byte gegevens in Byte4 |

-

Individuele parameter schrijfacties (communicatietype 18) (stroomuitval verlies)

| Gegevensdomein | 29-bits-ID | 8-byte gegevensveld | ||

| Dimensie | Bit28~bit24 | stukje23~8 | bit7~0 | Byte0~Byte7 |

| Beschrijving | 18 | bit15~8: gebruikt om de hoofd CAN_ID te identificeren | Doelmotor CAN_ID | Byte0~1: index, parameterlijst details Zie communicatietype 22 Byte2~3: 00 Byte4~7: parametergegevens |

Antwoordframe: Antwoordmotorfeedbackframe (zie communicatietype 2)

-

Foutfeedbackframes (communicatietype 21)

| Gegevensdomein | 29-bits-ID | 8-byte gegevensveld | ||

| Dimensie | Bit28~bit24 | stukje23~8 | bit7~0 | Byte0~Byte7 |

| Beschrijving | 21 |

bit15~8: gebruikt om te identificeren de belangrijkste CAN_ID |

Motor-CAN_ID | Byte0~3: foutwaarde (niet 0: defect, 0: normaal) bit16: Een fase stroommeting overstroom bit15~bit8:overbelasting fout bit7:Encoder niet gekalibreerd bit5:C fase stroommeting overstroom bit4:B fase stroommeting overstroom bit3:Overspanning fout bit2:Onder spanning fout bit1:Driver chip fout bit0: Motor overtemperatuur fout, standaard 80 graden. Byte4~7: waarschuwingswaarde Byte4~7: waarschuwingswaarde bit0: motor overtemperatuur waarschuwing, standaard 75 graden |

-

Baudet tariefwijziging (communicatietype 22) (raadpleeg de gedocumenteerde procedure en wijzig deze zorgvuldig, aangezien onjuiste handelingen kunnen leiden tot problemen zoals het niet kunnen aansluiten van de motor en het niet kunnen upgraden)

| Gegevensdomein | 29-bits-ID | 8-byte gegevensveld | ||

| Dimensie | Bit28~bit24 | stukje23~8 | bit7~0 | Byte0~Byte7 |

| Beschrijving | 22 |

bit15~8: gebruikt om te identificeren de belangrijkste CAN_ID |

Doelmotor CAN_ID | Byte0: Motor baudrate 1: 1 Mbps 2: 500 kbps 3: 250 kbps 4:125kbps |

Antwoordframe: Antwoordmotor-uitzendframe (zie communicatietype 0)

-

Individuele parameterlijsten kunnen worden gelezen en geschreven (7019-7020 zijn firmwareversie 1.2.1.5 leesbaar).

| Parameters index |

Parameter naam |

Beschrijving | Vriendelijk | Bytes | Eenheid/Beschrijving | R/W lees/schrijfrechten |

| 0X7005 | run_mode | 0: Operationele Controlemodus 1: Positiemodus 2: Snelheidsmodus 3: Huidige modus |

uint8 | 1 | W/R | |

| 0X7006 | iq_ref | Huidige modus Iq Commando |

vlot | 4 | -23~23A | W/R |

| 0X700A | spd_ref | RPM-modus RPM Commando |

vlot | 4 | -30~30rad/s | W/R |

| 0X700B | imit_torque | Koppellimiet | vlot | 4 | 0~12Nm | W/R |

| 0X7010 | cur_kp | Kp van stroom | vlot | 4 | Standaardwaarde 0,125 | W/R |

| 0X7011 | cur_ki | Ki van de huidige | vlot | 4 | Standaardwaarde 0,0158 | W/R |

| 0X7014 | cur_filt_gain | Huidig filter coëfficiënt filt_gain |

vlot | 4 | 0~1.0, standaardwaarde 0.1 | W/R |

| 0X7016 | loc_ref | Positiemodus Hoek commando |

vlot | 4 | tof | W/R |

| 0X7017 | limit_spd | Positiemodus Snelheidslimiet |

vlot | 4 | 0~30rad/s | W/R |

| 0X7018 | limit_cur | Snelheidspositie Modus Stroomlimiet |

vlot | 4 | 0~23A | W/R |

| 0x7019 | mechPos | Laad eindmaat Mechanische hoek |

vlot | 4 | tof | R |

| 0x701A | IQF | Iq-filterwaarde | vlot | 4 | -23~23A | R |

| 0x701B | mechVel | Snelheid aan de lastzijde | vlot | 4 | -30~30rad/s | R |

| 0x701C | VBUS | busbarspanning | vlot | 4 | V | R |

| 0x701D | rotatie | aantal ronden | int16 | 2 | aantal ronden | W/R |

| 0x701E | loc_kp | kp van positie | vlot | 4 | Standaardwaarde 30 | W/R |

| 0x701F | spd_kp | kp van snelheid | vlot | 4 | Standaardwaarde 1 | W/R |

| 0x7020 | spd_ki | ki van de snelheid | vlot | 4 | Standaardwaarde 0,002 | W/R |

Veelgestelde vragen

Q1: Wat is de maximale temperatuur die de Xiaomi cybergear motorbesturingskaart kan bereiken?

A1: Onder normale bedrijfsomstandigheden is de maximale bedrijfstemperatuur van de Xiaomi CyberGear motor besturingskaart doorgaans rond de 80°C. Echter, tijdens pieklasten of hoge prestaties kan de temperatuur van kritieke componenten zoals MOSFET's en spanningsregelaars tijdelijk oplopen tot 100°C tot 120°C (212°F tot 248°F).

Om een betrouwbare werking te waarborgen en thermische schade te voorkomen, wordt aanbevolen om geschikte koelingsoplossingen te implementeren, zoals koellichamen, ventilatoren of een goede ventilatie, om de temperaturen effectief te beheersen en de levensduur van het apparaat te verlengen.

Aanbevolen artikelen

Meer informatie

openelab.de

openelab.de

openelab.com

openelab.com