Resin 3D-utskrift har blivit en av de mest omvälvande teknologierna inom additiv tillverkning, vilket möjliggör skapandet av mycket detaljerade, släta och funktionella delar inom branscher som tandvård 🦷 och smycken 💍 till teknik ⚙️ och konsumentprodukter 🛍️. Inom resin-utskrift dominerar tre stora teknologier landskapet: SLA (stereolitografi), DLP (digital ljusbearbetning) och MSLA (maskad stereolitografi, ofta LCD-baserad). Var och en av dessa metoder har unika styrkor och kompromisser, och att förstå deras skillnader är avgörande för både yrkesverksamma och hobbyister.

Denna artikel utforskar skillnaderna mellan SLA, DLP och MSLA, baserat på allmänna jämförelser och lyfter fram Heygears UltraCraft Reflex 2 som en fallstudie av modern MSLA-innovation 🔬.

1. Grunderna i hartsskrivning 🌊💡

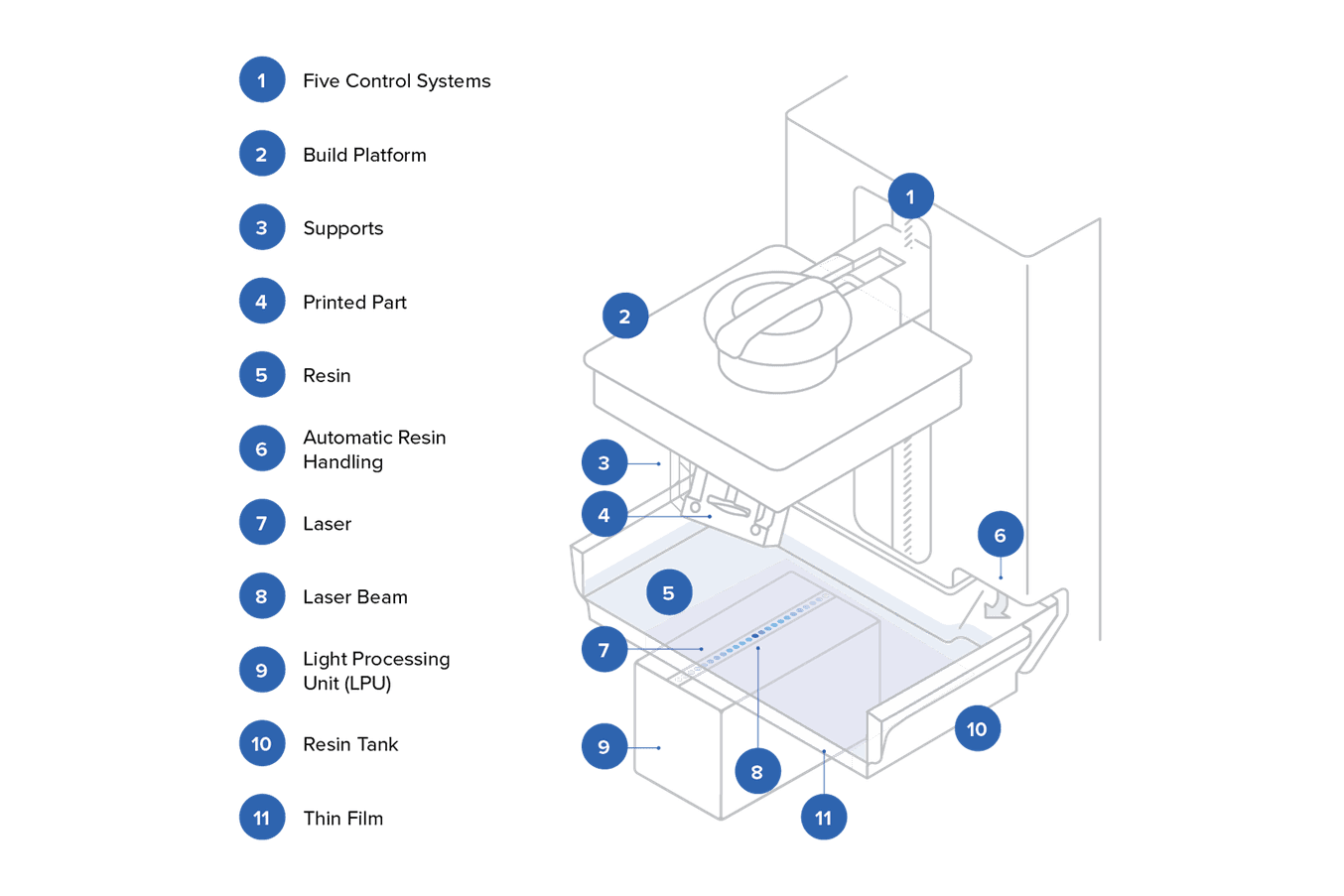

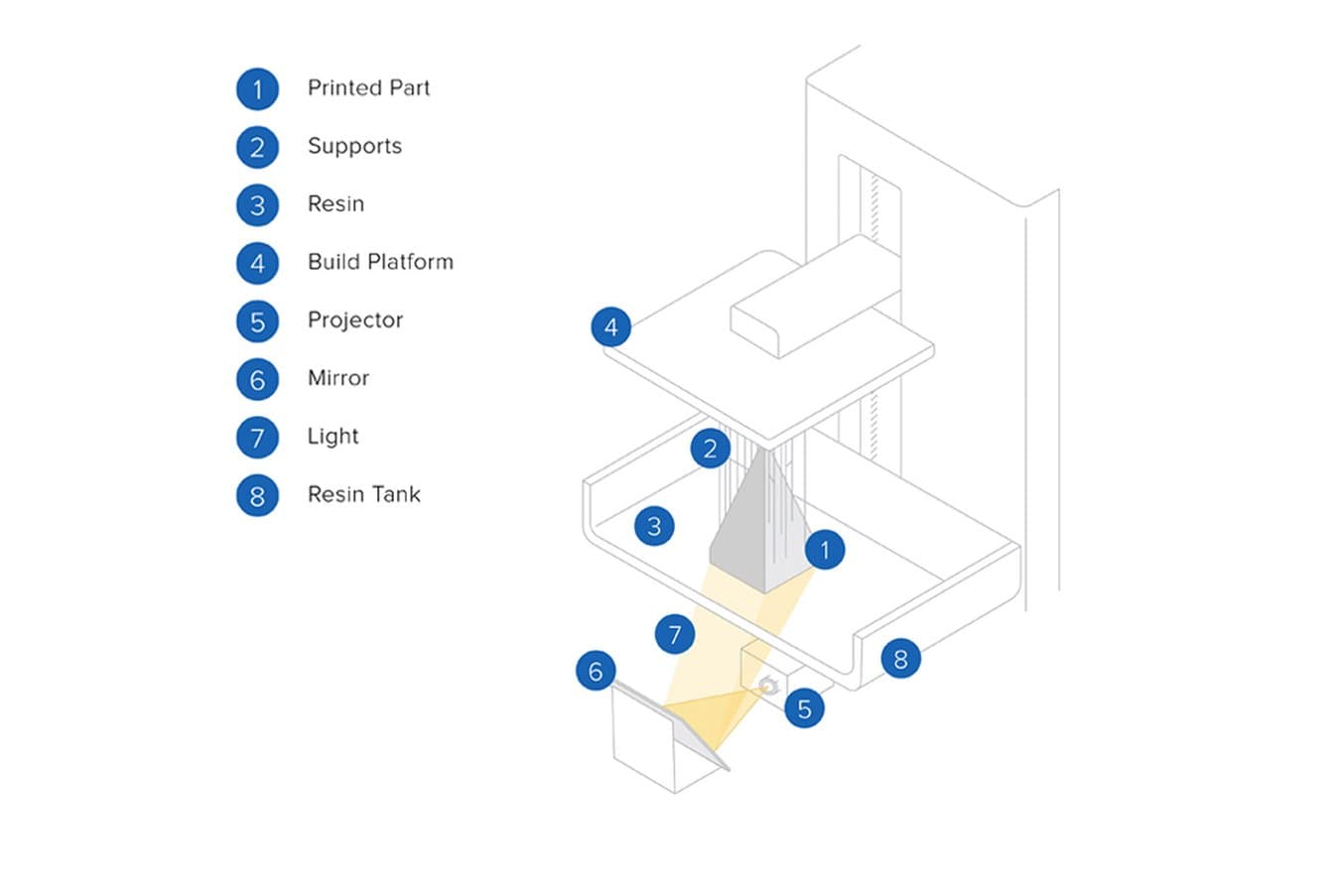

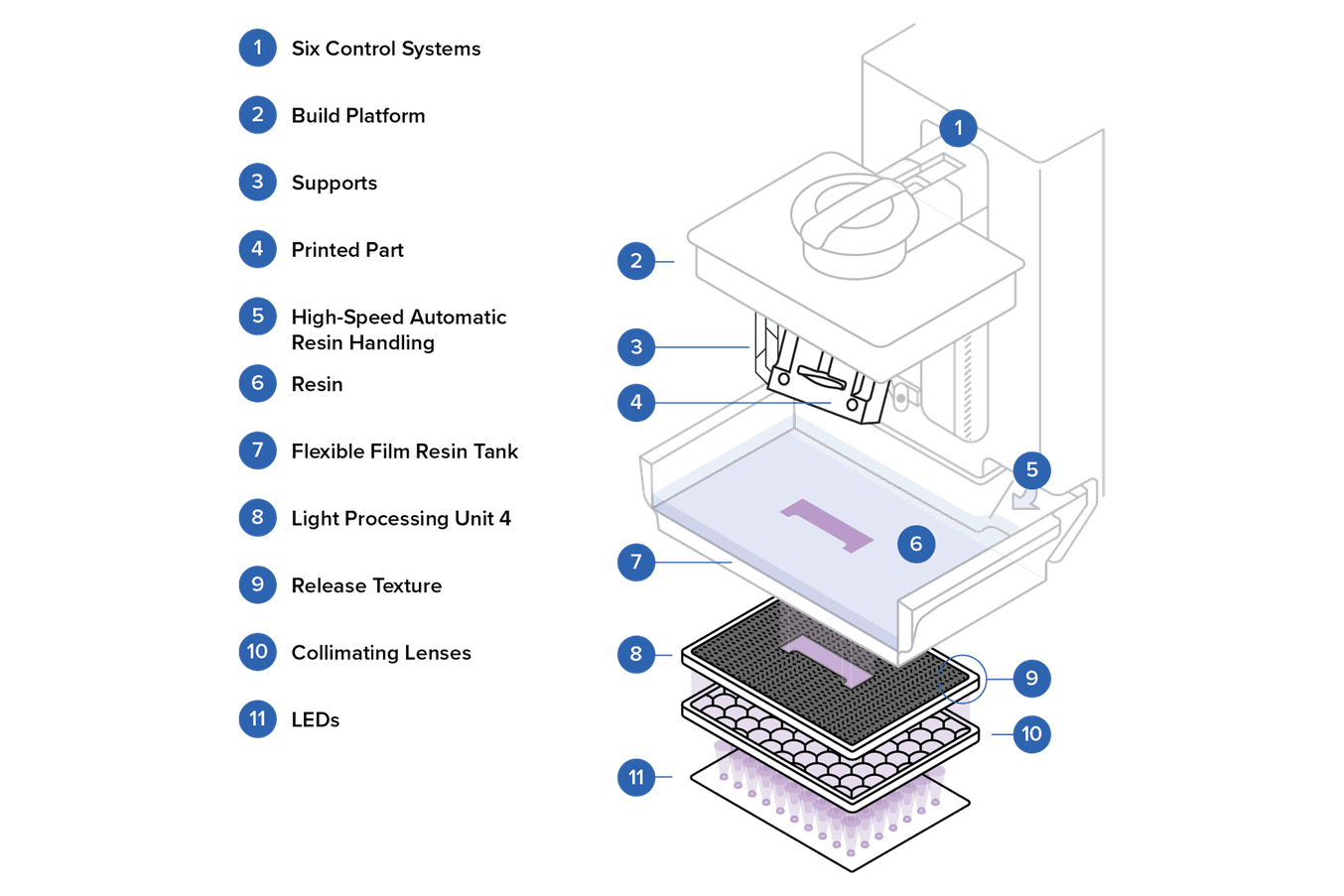

Hartsskrivning bygger på fotopolymerisation: flytande harts härdas selektivt med ljus för att bilda solida lager. Skillnaderna mellan SLA, DLP och MSLA ligger i hur ljuset levereras:

-

SLA 🔦 använder en laserstråle som spårar varje lager punkt för punkt.

-

DLP 🎥 projicerar ett helt lager på en gång med en digital projektor.

-

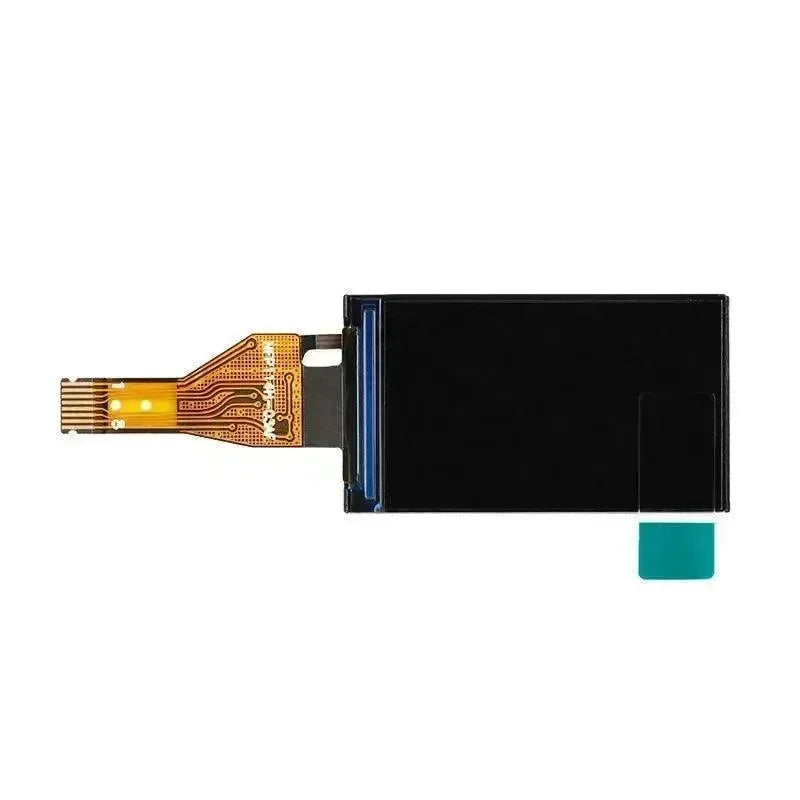

MSLA 📱 använder en LCD-skärm som mask, med en matris av lysdioder som lyser igenom.

2. SLA: Precision och ytkvalitet 🎯

Styrkor

-

🪞 Hög precision: Laserpunktstorlekar kan vara extremt små.

-

🌟 Släta ytor: Utmärkt finish för visuella prototyper.

-

🧪 Materialmångsidighet: Bred kompatibilitet med hartser.

Begränsningar

-

🐢 Långsammare hastighet.

-

📏 Skalningsutmaningar för stora konstruktioner.

-

💰 Högre kostnader.

Bäst för: Medicinska enheter 🩺, tandmodeller 🦷, smyckesmästare 💎, transparenta prototyper 🔍.

3. DLP: Hastighet och effektivitet ⚡

Styrkor

-

🚀 Snabb utskrift: Hela lager härdas samtidigt.

-

📐 God precision: Pixelbaserad upplösning.

-

🏭 Effektivt för små serier.

Begränsningar

-

🔍 Upplösningen minskar med större volymer.

-

🪜 Pixeleringseffekter möjliga.

-

💸 Projektorkostnaden blir hög.

Bäst för: Tandlaboratorier 🦷, smyckestillverkning 💍, snabb prototypframställning ⚙️.

4. MSLA (LCD): Tillgänglighet och innovation 🌍

Styrkor

-

💵 Kostnadseffektiv: Prisvärd startpunkt.

-

📱 Hög upplösning med 4K/8K LCD.

-

⏱️ Snabb härdning av lager.

-

📦 Stora byggvolymer möjliga.

Begränsningar

-

⏳ LCD-paneler försämras med tiden.

-

🌈 Problem med ljusuniformitet vid dålig kalibrering.

-

🧴 Begränsad resin-kompatibilitet på vissa modeller.

Bäst för: Makers 👩🔧, små studior 🎨, utbildning 🎓, och nu professionell användning tack vare avancerade modeller.

5. Fallstudie: Heygears UltraCraft Reflex 2 🏆

The Heygears UltraCraft Reflex 2 visar hur MSLA har utvecklats till en professionell lösning.

Höjdpunkter

-

🎯 XY-upplösning: 40 μm.

-

📦 Byggvolym: 230 × 144 × 230 mm.

-

🔆 OptiZone ljusmotor med 161 mini-LEDs.

-

🛡️ Amber Screen Pro: >6000 timmars livslängd.

-

🤖 AI-ljuskalibrering: noggrannhet ±0,05 mm.

-

🌡️ Smart hartsuppvärmning & hantering.

-

🌐 Anslutning: USB, Wi-Fi, LAN.

Denna skrivare visar att MSLA kan konkurrera med SLA och DLP i professionella sammanhang, med en balans mellan hastighet ⚡, precision 🎯 och prisvärdhet 💵.

6. Jämförande analys 📊

| Funktion | SLA 🔦 | DLP 🎥 | MSLA 📱 |

|---|---|---|---|

| Ljus källa | Laser | Projektor | LED-array + LCD-mask |

| Upplösning | 25–100 μm | 35–100 μm | 35–50 μm |

| Hastighet | 🐢 Långsam | 🚀 Snabb | 🚀 Snabb |

| Ytkvalitet | 🌟 Utmärkt | 🙂 Bra, pixlig | 🙂 Bra, rutnätsartefakter |

| Byggvolym | Stor men långsam | Begränsad skalning | Stor, skalbar |

| Kostnad | 💰 Högre | 💸 Högre | 💵 Lägre–mellansegment |

| Hållbarhet | 🛡️ Hög | 🛡️ Hög | ⏳ LCD-livslängd begränsad |

| Bäst för | Detaljprototyper 🎨 | Tandvård/smycken 🦷💍 | Hobbyister & proffs 👩🔧🏭 |

7. Välja rätt teknik 🧭

-

🎯 SLA: Bäst för ultrafina detaljer och slät finish.

-

⚡ DLP: Bäst för hastighet och effektivitet.

-

🌍 MSLA: Bäst för prisvärdhet och skalbarhet, nu professionell kvalitet med Reflex 2.

8. Resin-utskriftens framtid 🔮

Resin-utskriftsteknologier närmar sig varandra: SLA blir snabbare, DLP mer precis och MSLA mer hållbar. Hybridmetoder kan uppstå som kombinerar styrkor. Reflex 2 visar att MSLA kan leverera industriell prestanda till tillgängliga kostnader och omforma marknaden.

Slutsats ✅

SLA, DLP och MSLA representerar var och en unika tillvägagångssätt för resin 3D-utskrift:

-

SLA = 🎯 precision + 🌟 finish

-

DLP = ⚡ hastighet + 🏭 effektivitet

-

MSLA = 🌍 tillgänglighet + 💵 prisvärdhet

Med innovationer som Heygears UltraCraft Reflex 2 🏆 bevisar MSLA att det kan stå sida vid sida med SLA och DLP i professionella miljöer. Valet beror slutligen på om din prioritet är detalj, hastighet eller kostnad.