Resin 3D-printning er blevet en af de mest transformerende teknologier inden for additiv fremstilling, der muliggør skabelsen af meget detaljerede, glatte og funktionelle dele på tværs af industrier fra tandpleje 🦷 og smykker 💍 til ingeniørarbejde ⚙️ og forbrugerprodukter 🛍️. Inden for resinprintning dominerer tre store teknologier landskabet: SLA (stereolitografi), DLP (digital lysbehandling) og MSLA (masked stereolitografi, ofte LCD-baseret). Hver af disse metoder har unikke styrker og kompromiser, og det er afgørende for både professionelle og hobbyister at forstå deres forskelle.

Denne artikel undersøger forskellene mellem SLA, DLP og MSLA, baseret på generelle sammenligninger og fremhæver Heygears UltraCraft Reflex 2 som et casestudie i moderne MSLA-innovation 🔬.

1. Grundlæggende om resinprintning 🌊💡

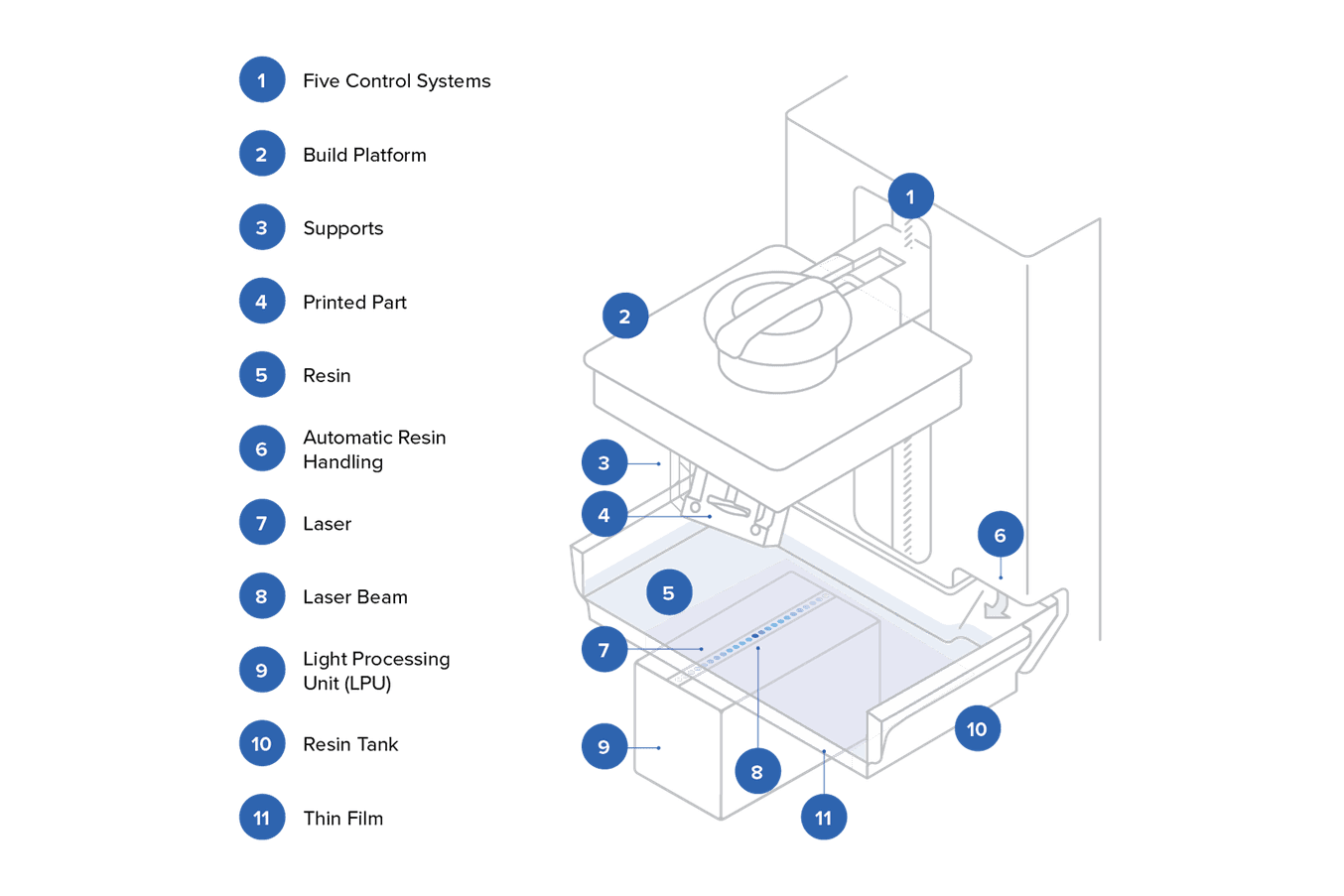

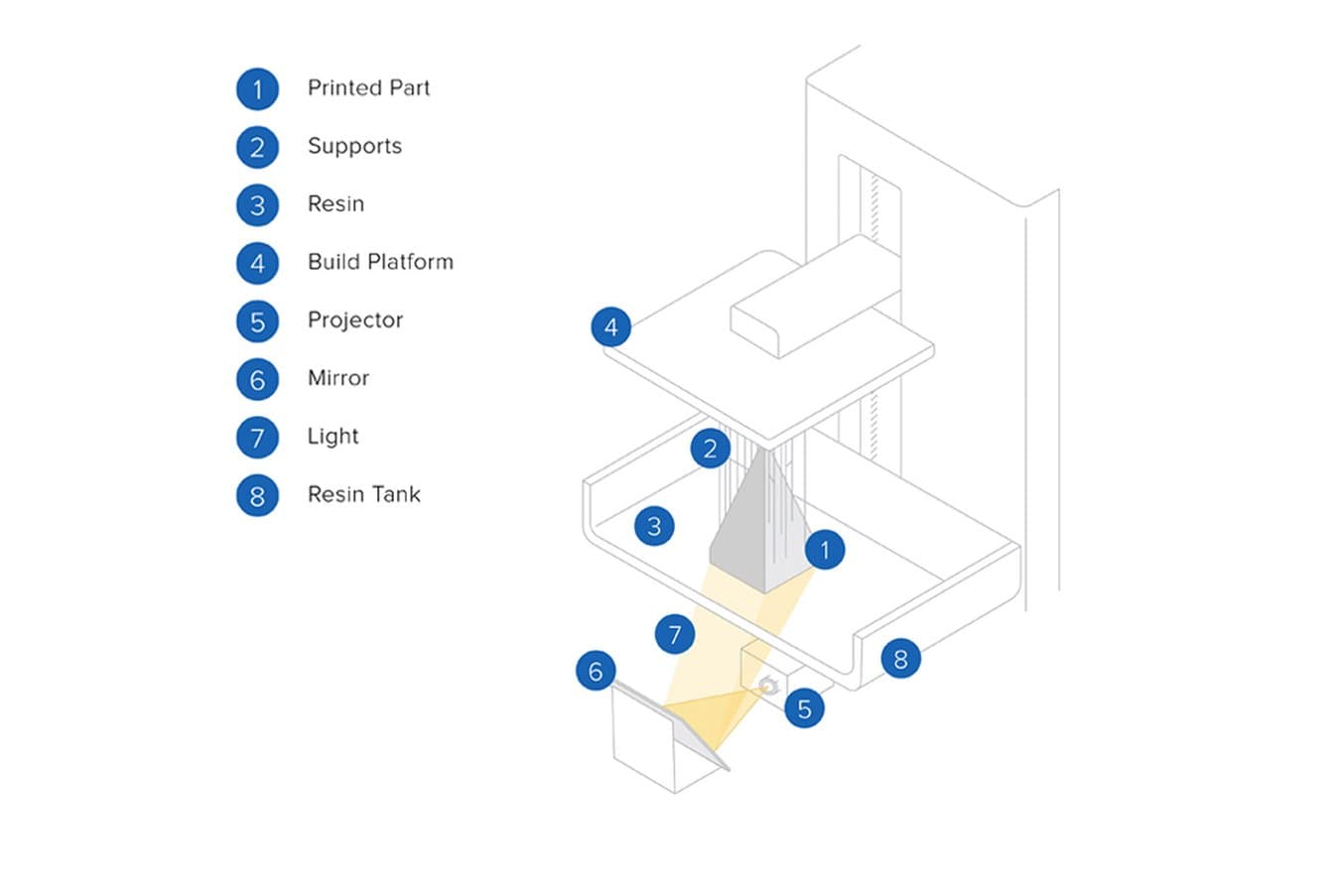

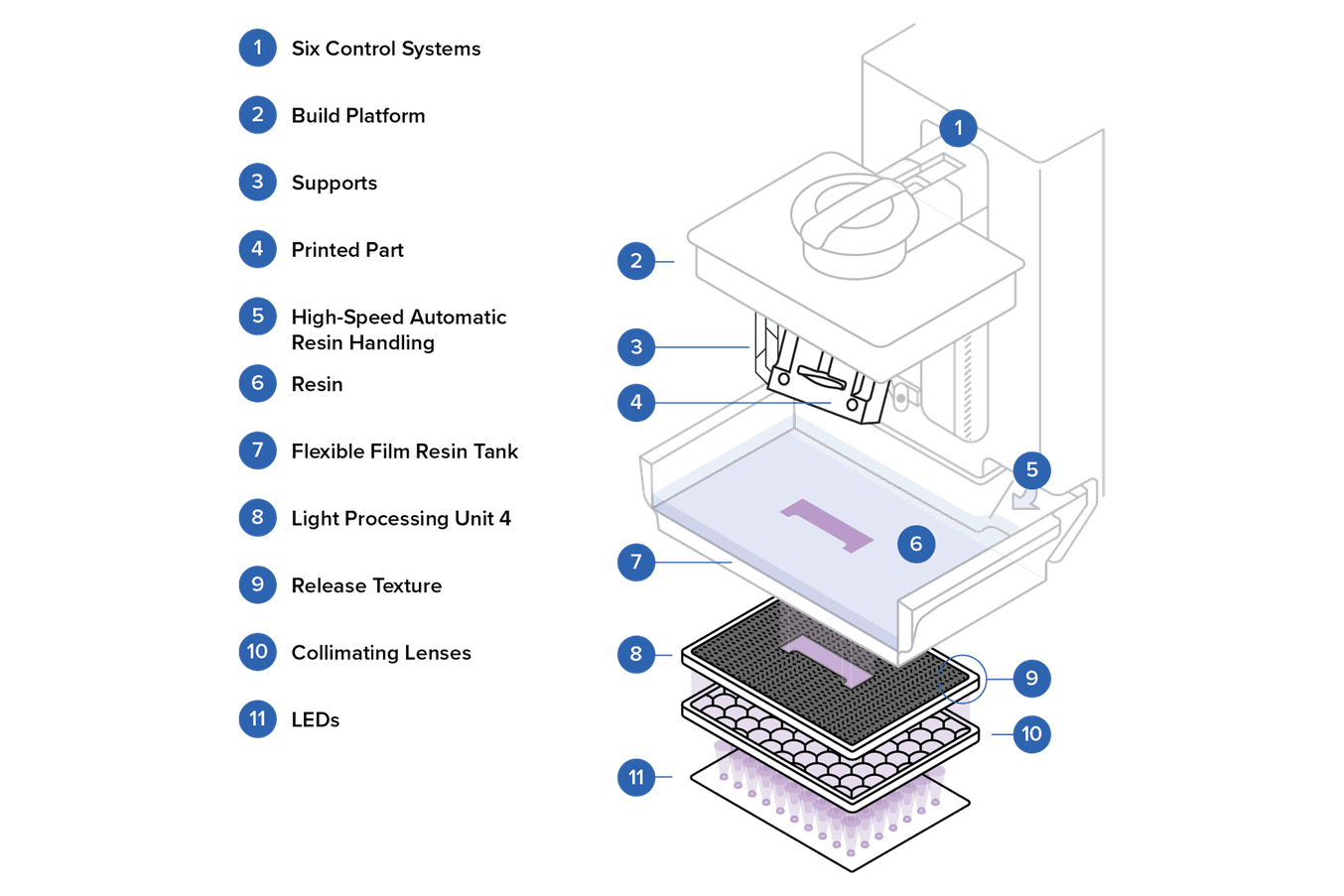

Resinprintning bygger på fotopolymerisation: flydende resin hærdes selektivt af lys for at danne faste lag. Forskellene mellem SLA, DLP og MSLA ligger i hvordan lyset leveres:

-

SLA 🔦 bruger en laserstråle, der sporer hvert lag punkt for punkt.

-

DLP 🎥 projicerer et helt lag på én gang ved hjælp af en digital projektor.

-

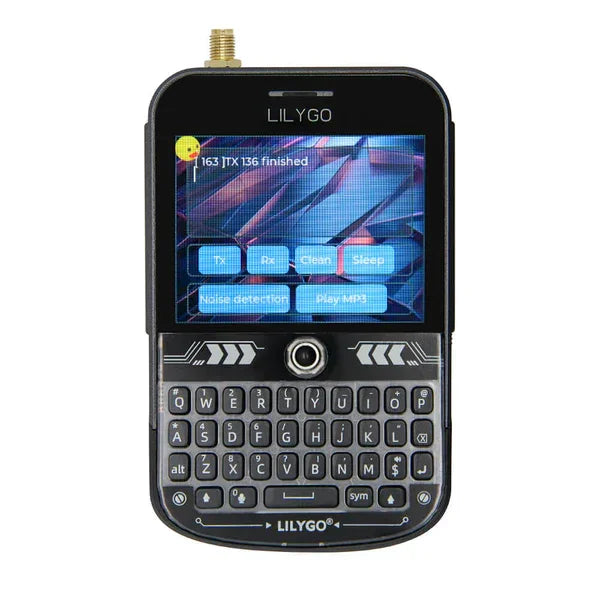

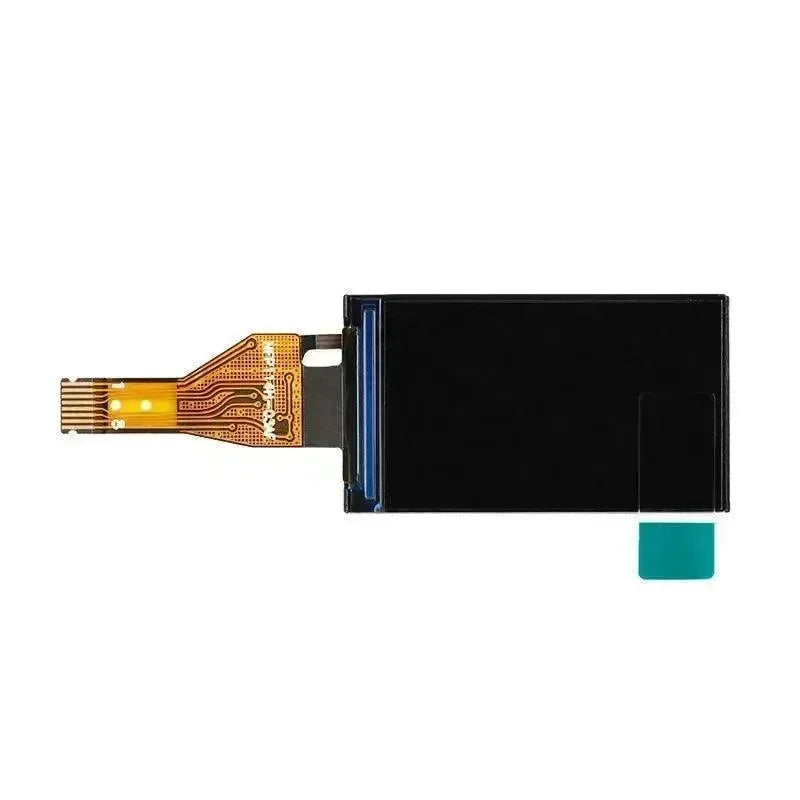

MSLA 📱 bruger en LCD-skærm som maske, med en række LED'er, der skinner igennem.

2. SLA: Præcision og overfladekvalitet 🎯

Styrker

-

🪞 Høj præcision: Laserspotstørrelser kan være ekstremt fine.

-

🌟 Glatte overflader: Fremragende finish til visuelle prototyper.

-

🧪 Materiale alsidighed: Bred resin kompatibilitet.

Begrænsninger

-

🐢 Langsommere hastighed.

-

📏 Skaleringsudfordringer for store konstruktioner.

-

💰 Højere omkostninger.

Bedst til: Medicinsk udstyr 🩺, tandmodeller 🦷, smykkemestre 💎, gennemsigtige prototyper 🔍.

3. DLP: Hastighed og effektivitet ⚡

Styrker

-

🚀 Hurtig printning: Hele lag hærdes på én gang.

-

📐 God præcision: Pixelbaseret opløsning.

-

🏭 Effektiv til små partier.

Begrænsninger

-

🔍 Opløsningen falder med større volumener.

-

🪜 Pixelering kan forekomme.

-

💸 Projektoromkostninger løber op.

Bedst til: Tandlægelaboratorier 🦷, smykkestøbning 💍, hurtig prototyping ⚙️.

4. MSLA (LCD): Tilgængelighed og innovation 🌍

Styrker

-

💵 Omkostningseffektiv: Overkommelig indgangspris.

-

📱 Høj opløsning med 4K/8K LCD-skærme.

-

⏱️ Hurtig laghærdning.

-

📦 Store byggevolumener mulige.

Begrænsninger

-

⏳ LCD-paneler forringes over tid.

-

🌈 Lysens ensartethed kan være et problem ved dårlig kalibrering.

-

🧴 Begrænset harpiks-kompatibilitet på nogle modeller.

Bedst til: Makers 👩🔧, små studier 🎨, uddannelse 🎓 og nu professionel brug takket være avancerede modeller.

5. Case Study: Heygears UltraCraft Reflex 2 🏆

The Heygears UltraCraft Reflex 2 viser, hvordan MSLA er udviklet til en professionel løsning.

Højdepunkter

-

🎯 XY-opløsning: 40 μm.

-

📦 Byggevolumen: 230 × 144 × 230 mm.

-

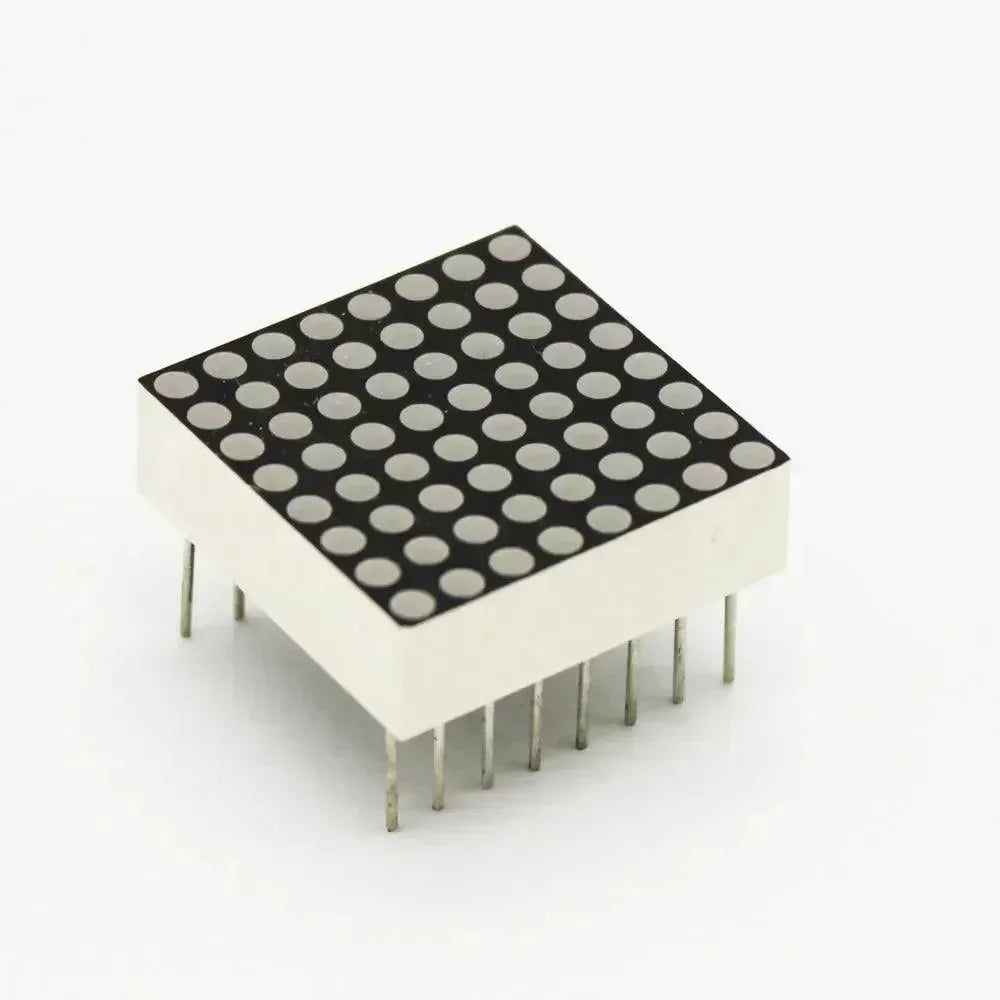

🔆 OptiZone lysmotor med 161 mini-LEDs.

-

🛡️ Amber Screen Pro: >6000 timers levetid.

-

🤖 AI-lys kalibrering: nøjagtighed ±0,05 mm.

-

🌡️ Smart harpiksopvarmning og -styring.

-

🌐 Forbindelse: USB, Wi-Fi, LAN.

Denne printer beviser, at MSLA kan konkurrere med SLA og DLP i professionelle sammenhænge ved at balancere hastighed ⚡, præcision 🎯 og overkommelighed 💵.

6. Sammenlignende analyse 📊

| Funktion | SLA 🔦 | DLP 🎥 | MSLA 📱 |

|---|---|---|---|

| Lyskilde | Laser | Projektor | LED-array + LCD-maske |

| Opløsning | 25–100 μm | 35–100 μm | 35–50 μm |

| Hastighed | 🐢 Langsom | 🚀 Hurtig | 🚀 Hurtig |

| Overfladekvalitet | 🌟 Fremragende | 🙂 God, pixelering | 🙂 God, gitterartefakter |

| Byggevolumen | Stor men langsom | Begrænset skalering | Stor, skalerbar |

| Pris | 💰 Højere | 💸 Højere | 💵 Lavere–mellemklasse |

| Holdbarhed | 🛡️ Høj | 🛡️ Høj | ⏳ LCD-levetid begrænset |

| Bedst til | Detaljeprototyper 🎨 | Tandlæge/smykker 🦷💍 | Hobbyister & professionelle 👩🔧🏭 |

7. Valg af den rigtige teknologi 🧭

-

🎯 SLA: Bedst til ultra-fine detaljer og glat finish.

-

⚡ DLP: Bedst til hastighed og effektivitet.

-

🌍 MSLA: Bedst til overkommelighed og skalerbarhed, nu professionel kvalitet med Reflex 2.

8. Fremtiden for resin-print 🔮

Resin-printteknologier nærmer sig hinanden: SLA bliver hurtigere, DLP mere præcis, og MSLA mere holdbar. Hybridtilgange kan opstå, der kombinerer styrker. Reflex 2 viser, at MSLA kan levere industriel ydeevne til tilgængelige priser og omforme markedet.

Konklusion ✅

SLA, DLP og MSLA repræsenterer hver unikke tilgange til resin 3D-print:

-

SLA = 🎯 præcision + 🌟 finish

-

DLP = ⚡ hastighed + 🏭 effektivitet

-

MSLA = 🌍 tilgængelighed + 💵 overkommelighed

Med innovationer som Heygears UltraCraft Reflex 2 🏆 beviser MSLA, at det kan stå skulder ved skulder med SLA og DLP i professionelle miljøer. Valget afhænger i sidste ende af, om din prioritet er detalje, hastighed eller pris.